CNC Wire-Cutting, Mirror Electrical Discharge, Processing of High Speed Milling Machine and FormingGrinding.

Precision Plastic Mold Designing,Manufacturing, Plastic Injection Molding and Metal Injection Molding.

Pulse power to strengthen the adhesion

Flexible space design

Target material effect varied

-

Plastic injection

Plastic injection

-

Optical design

Optical design

-

Sputtering foundry

Sputtering foundry

-

Medical products

Medical products

-

Automotive Products

Automotive Products

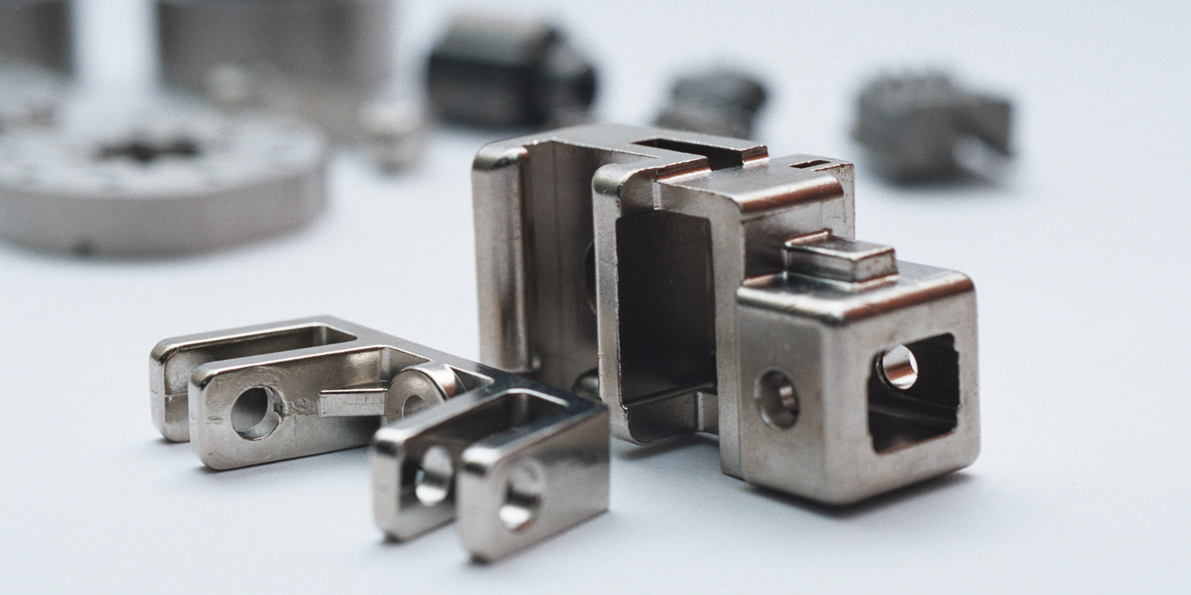

Core Technology

1.CNC / line cutting, mirror discharge, high-speed milling machine, forming grinding processing

2.Precision plastic mold design, manufacturing, plastic injection molding

3.Excellent design capabilities and continuous research and development technology, the pursuit of high-quality mold and high-precision

Operational policy:

- Precision plastic whole process development

- Cost and process strategy

- Cross - industry technology integration

- New market new areas

- Train services

Business project:

- Optical design

- Mold manufacturing

- Precision molding

- Spraying, printing, assembly

- Vacuum sputtering

Optical technology

1.Improve the efficiency of light, in the same light-emitting angle requirements, the rich design can be more common than the general increase10%~20%

2.Uniform illumination, the use of unique optical design, so that the illumination is more uniform, more comfortable in space

3.Effective handling of yellow halo problems, unique experience for light control, can effectively deal with yellow halo problems

4.Solve the imaging problem, there are many ways to solve the imaging problem, while not causing the loss of efficiency

Vacuum sputtering

1.Machine self-development, hardware and software research and development by their own research and development, in the operation of the application can be adjusted

2.Pulse power, enhanced adhesion, unique power supply design to strengthen the plasma ion kinetic energy, significantly enhance the adhesion

3.Elastic space design, can be double-sided and large size of the object coating, breaking the traditional 9cm limit

4.Target material effect varied, through the strengthening of the sputtering energy, allowing the product at the same time there are different metallic texture

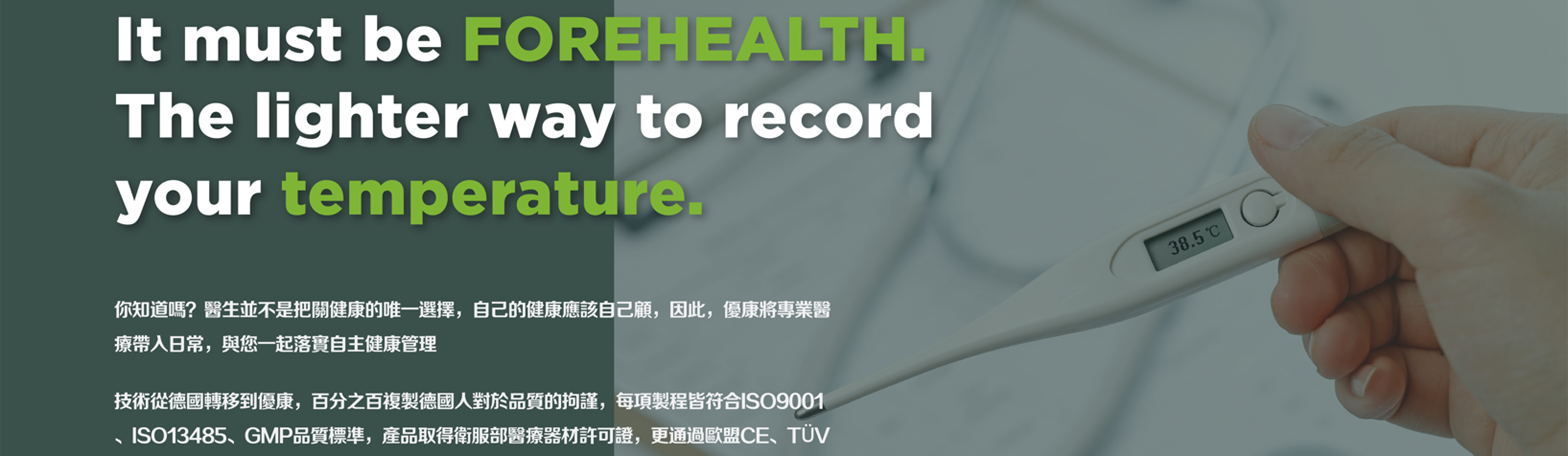

Medical Products

1. To cope with new market needs and currency, Actherm Medical Corp. produces series digital thermometers with innovative technology and ergonomic design

2.With CE, FDA, CFDA, GMP certifivation and ISO13485 quality assurance

3.OEM & ODM available

4. A series production of Digital Thermometer / Infrared Thermometer /Probe Cover

Digital Thermometer - flexible & rigid tip optional, classic & 10-second fast read, 100% waterproof,

basal & hypothermia available

Infrared Ear Thermometer - Ideal design,simple pack, cradle available, home use & hospital solution,

wireless transmission

Probe Cover - ensuring hygienic use with accurate temperature reading, fit most digital ear thermometer

Automotive Products

1.Rich experience in molding and injection of precision parts

2.Products can be customized for different requirments

3.Engineering team and focus on the process

4.With iso16949 quality assurance

5. Own assembly line, One-stop service

© Copyright 2024 FORTECH Joomla Templates by JoomDev